- TYRE BUILDING BLADDER

- CARCASS DRUM SLEEVE

- SHAPING DRUM SLEEVE

- SHAPING DRUM BLADDER

- PUSH OVER BLADDER

- TURN UP BLADDER

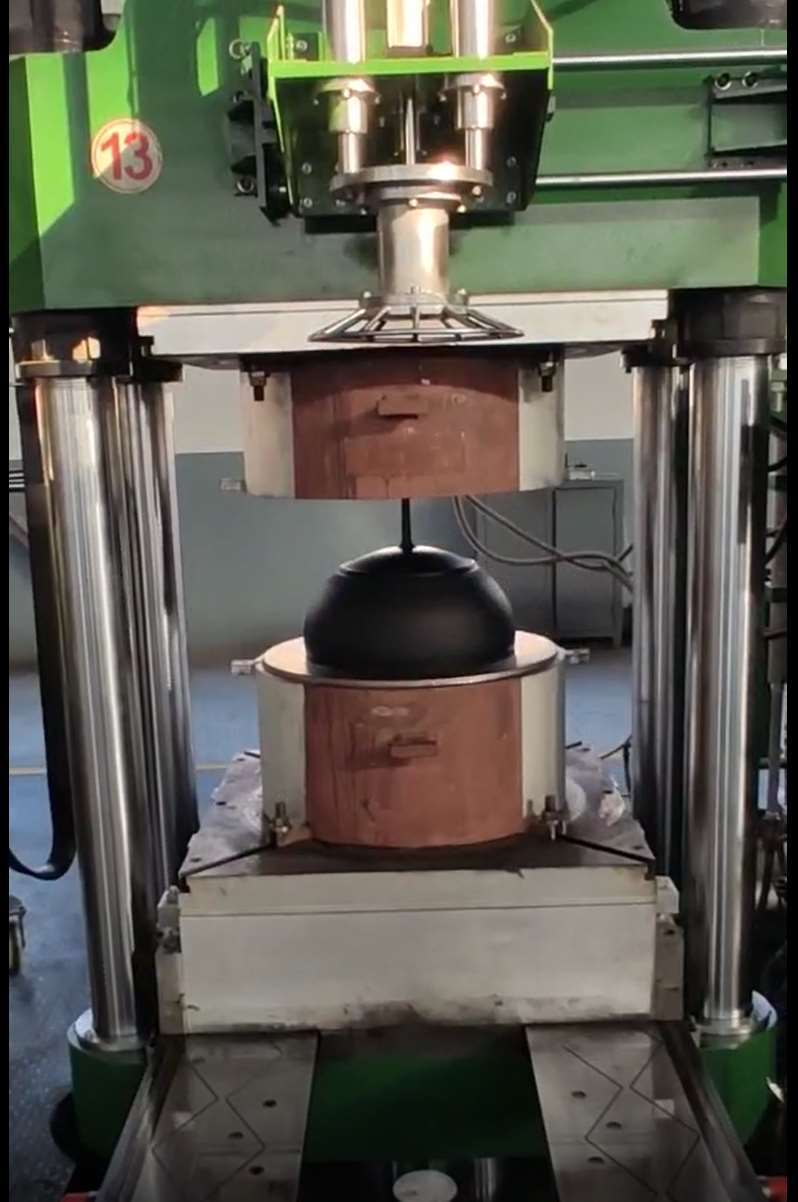

- TYRE CURING BLADDER

- AIR SPRING CURING BLADDER

- B TYPE SEMI-STEEL RADIAL TYRE CURING BLADDER FOR PCR & LTR

- C TYPE SEMI-STEEL RADIAL TYRE CURING BLADDER FOR PCR & LTR

- B TYPE ALL STEEL RADIAL TYRE CURING BLADDER FOR TBR

- A TYPE RADIAL TYRE CURING BLADDER FOR PCR & LTR

- AB TYPE RADIAL TYRE CURING BLADDER FOR PCR & LTR

- B TYPE CURING BLADDER FOR BIAS TRUCK & BUS (TBB) TIRE

- B TYPE CURING BLADDER FOR BIAS INDUSTRIAL & OTR TIRE

- B TYPE CURING BLADDER FOR RADIAL INDUSTRIAL & OTR TIRE

- B TYPE CURING BLADDER FOR BIAS AGRICULTURAL (AG) TIRE

- B TYPE CURING BLADDER FOR MERIDIAN AGRICULTURAL (MG) TIRE

- B TYPE CURING BLADDER FOR MOTORCYCLE TIRE

- B TYPE CURING BLADDER FOR CYCLE/MOTORCYCLE TIRE

BUTYL RUBBER B TYPE SEMI-STEEL RADIAL TYRE CURING BLADDER FOR PCR & LTR

INSTRUCTIONS :

The tyre curing bladder (hereinafter referred to as curing bladder) is an essential tool in vulcanization of tyre.

The quality of the curing bladder is closely related not only to the production cost but also to the quality of tyre.

In order to extend the curing bladder service life and avoid unnecessary losses, please refer to instructions carefully.

Pre-storage inspection:

1. Please check whether the package is complete and the curing bladder size is clearly identified before storage.

2. Please inspect the curing bladder according to the “Tyre Curing Bladder Standard”(Q/JTD001 -2003) we have provided or according to the contract requirement.

3. Each curing bladder is attached with a Tyre Curing Bladder Performance Record Form in each bag or each case.

4. If you find the goods do not meet your requirements, please keep them as they are and contact us immediately so that we can provide faster and better service for you.

Storage Conditions :

5. In order to avoid possible deformation during long-time storage, the height for bagged curing bladders must not exceed 6 layers or 2500mm.

6. Store the curing bladders under room temperature, keep them away from chemicals and heat sources, prevent them from sunlight, and what’s more, curing bladders must be kept away from any oil.

7. It is better not to open the case 48 hours before use in case the storage conditions are in conflict with the above article 6.

8. The OTR curing bladder must be resumed to its original shape before being put in storage.

9. Please take care to prevent curing bladders from any sharp objects to avoid any possible hard damages under storage and transportation conditions.

Bladder Code | Foot I.D dB (mm) | Foot Height a (mm) | Foot Width b (mm) | Foot Gauge to' (mm) | Central Gauge to(mm) | Outside Diameter DB (mm) |

Over-all Height HB (mm)

|

Effective Periphery LB(mm) |

Etching

Pattern |

Applied Tyre section

|

B600R9-1 | 150 | 19 | 10 | 8 | 6 | 374 | 271 | 361 | ||

P327 | 197 | 21.4 | 11.7 | 9.5 | 4 | 406 | 203 | 311 | ||

B135R12-1 | 210 | 22 | 12 | 9 | 5.5 | 392 | 224 | 290 | 135/145R12 | |

RTB12-284 | 224 | 21 | 11 | 7.5 | 5 | 375 | 230 | 284 | 185/35R12 165/40R12 | |

B155R12-1 | 224 | 21.5 | 12 | 7 | 5 | 408 | 240 | 310 | 145/70R12 155/55R12 | |

B145R12-1 | 224 | 21 | 12 | 7 | 5.7 | 450 | 228 | 332 | 145/165R12/13 | |

B145R12-1(3) | 224 | 21 | 12 | 7 | 5.7 | 450 | 228 | 332 | 145/165R12/13 | |

B145R12-2 | 224 | 21 | 12 | 7 | 5 | 450 | 228 | 332 | ||

B145R12-3 | 224 | 21 | 13 | 7.5 | 5 | 465 | 235 | 334 | ||

B155R13-2 | 224 | 23 | 12 | 8 | 5 | 430 | 274 | 350 | 155/70R13 | |

B175R13-3 | 224 | 21 | 12.5 | 7 | 4.5 | 460 | 286 | 376 | 155R13LT 165(175)/70R13 | |

B175R13-3(2) | 224 | 21 | 12.5 | 7 | 4.5 | 460 | 286 | 376 | 155R13LT 165(175)/70R13 | |

JS0340 | 228 | 24 | 12 | 7.5 | 4.5 | 450 | 290 | 383 | ||

B185R14-4 | 224 | 23 | 12.5 | 8 | 4.5 | 460 | 312 | 400 | ||

B195R14-2 | 224 | 23 | 12.5 | 8 | 4.5 | 480 | 320 | 420 | ||

RTB12-490 | 228 | 23.5 | 12 | 8 | 5 | 530 | 330 | 492 | 205/70R14 215/75R14 | |

B135R13-1 | 234 | 21 | 12 | 10 | 6.2 | 415 | 203 | 273 | 135/165R13 | |

B145R13-1 | 234 | 21 | 12 | 10 | 4.5 | 421 | 235 | 287 | 135/155R13 | |

B155R13-1 | 234 | 21 | 12 | 10 | 6.2 | 420 | 205 | 292 | 135/165R13 | |

B165R13-1 | 234 | 21 | 12 | 7.5 | 5 | 440 | 235 | 316 | 145/175R13 | |

B165R13-3 | 234 | 21 | 12 | 7.5 | 4 | 440 | 235 | 316 | 145/175R13 | |

P350 | 235 | 23 | 11.7 | 9.5 | 4 | 444 |

228

|

324

|

||

B155R13-3 | 234 | 21 | 12 | 7.5 | 5 | 440 | 250 | 330 | 155/65R13 | |

B165R13-2 | 234 | 21 | 12 | 10 | 4.5 | 460 | 260 | 346 | 165/65(70)R13 155R13 | |

B175R13-1 | 234 | 21 | 12 | 10 | 4.5 | 460 | 265 | 347 | 165/185R13 | |

RTB13-354 | 234 | 22 | 13 | 8 | 4.5 | 460 | 266 | 354 | B165R13-4(2) | |

B165R13-4 | 234 | 21 | 12 | 7.5 | 4 | 450 | 281 | 364 | 165/70R13 | |

B165R13-4(2) | 234 | 21 | 12 | 7.5 | 5 | 450 | 281 | 364 | 165/70R13 | |

B175R13-2 | 234 | 21 | 12 | 10 | 4 | 460 | 300 | 380 | 165/75R13 175/75(70)R13 185/70R13 | |

B175R13-2(2) | 234 | 22 | 12 | 8 | 4.8 | 460 | 300 | 380 | 165/75R13 175/75(70)R13 185/70R14 | |

B10X270X410 | 250 | 22 | 14 | 9 | 4.8 | 410 | 270 | 315 | ||

B10X250X460 | 250 | 22 | 14 | 9 | 5.3 | 460 | 250 | 331 | ||

RB14-0 | 250 | 21.5 | 13 | 8 | 4.5 | 460 | 258 | 335 | 165/60R14 | |

RB14-0-1 | 255 | 22.5 | 13 | 7.5 | 4.5 | 470 | 240 | 338 | 155/65R14 175/70R14 | |

B185R14-1 | 260 | 21 | 12 | 10 | 4.5 | 460 | 256 | 338 | 155/195R14 | |

B185R14-3 | 260 | 21 | 12 | 10 | 4.5 | 460 | 256 | 338 | 155/195R14 | |

B10X270X460 | 250 | 22 | 14 | 9 | 5.3 | 460 | 270 | 351 | ||

RTB14-370 | 250 | 21.5 | 12.5 | 7 | 4.5 | 490 | 275 | 370 | 175/70R14 | |

B195R14-1 | 250 | 22 | 13 | 9.5 | 4.5 | 460 | 294 | 370 | 185/195/60R14 | |

RB1401 | 260 | 22 | 12 | 8 | 5.3 | 460 | 302 | 371 | ||

B205R14-1 | 248 | 21 | 12 | 7 | 5 | 490 | 276 | 375 | 165/205R14/15 | |

B205R14-2 | 248 | 23 | 12 | 7 | 5 | 490 | 276 | 375 | 165/205R14/15 | |

B205R14-2(2) | 248 | 21 | 12 | 7 | 5 | 490 | 276 | 375 | 165/205R14/15 | |

RB14-1 | 250 | 22 | 13 | 9.5 | 5 | 470 | 266 | 376 | ||

B185R14-2 | 260 | 21.4 | 11.66 | 9.55 | 4.8 | 430 | 316 | 380 | 185/195/60R14 195/50R15 | |

RB14-1A | 260 | 22 | 12.7 | 8 | 5.3 | 490 | 295 | 385 | ||

B10"X300X470-1 | 250 | 22 | 14 | 9 | 5.3 | 470 | 300 | 388 | ||

B10"X300X470-2 | 250 | 22 | 14 | 9 | 4.8 | 470 | 300 | 388 | ||

JTB1651 | 248 | 21 | 12 | 7.3 | 5 | 485 | 270 | 389 | ||

B185R14-5 | 248 | 23 | 12 | 7 | 5 | 490 | 316 | 410 | ||

JTB14-S-390 | 248 | 22 | 14 | 8.4 | 5.5 | 478 | 308 | 415 | 185/70R14 | |

JTB14-S-390 | 248 | 22 | 14 | 8.4 | 5.5 | 478 | 308 | 415 | ||

RB14-2 | 250 | 22.5 | 12 | 9 | 4.8 | 520 | 300 | 420 | ||

RB14-2(2) | 250 | 22 | 12 | 9.5 | 5 | 520 | 300 | 420 | ||

B10"X350X470-1 | 250 | 22 | 14 | 9 | 5.3 | 470 | 350 | 438 | ||

B10"X350X470-2 | 250 | 22 | 14 | 9 | 4.8 | 470 | 350 | 438 | ||

RTB14-438 | 250 | 22 | 13 | 8 | 5.3 | 520 | 316 | 438 | 185R14C | |

B205R14-3 | 248 | 21 | 12 | 7 | 4 | 510 | 342 | 442 | 205/70(75/80)R14 | |

B650R16-1 | 250 | 22 | 13 | 9.5 | 6 | 545 | 370 | 485 | 650R16 7.00R16 195/215/65R15 | |

B650R16-2 | 250 | 22 | 13 | 9.5 | 6 | 545 | 370 | 485 | 650R16 7.00R16 195/215/65R15 | |

B195R15-1 | 285 | 21 | 11.7 | 10 | 5 | 450 | 278 | 344 | ||

B155R15-1 | 285.7 | 21.38 | 11.659 | 6.58 | 4.06 | 508 | 265.8 | 364 | 155R15 | |

B155R15-1(2) | 285.7 | 21.38 | 11.659 | 9.6 | 5 | 508 | 266 | 364 | 155R15 | |

B518-D | 276 | 20.5 | 14.2 | 9 | 5.2 | 406 | 323.5 | 372 | ||

B518-D | 276 | 20.5 | 14.2 | 9 | 5.2 | 406 | 323.5 | 372 | ||

RTB15-378 | 276 | 23 | 12.5 | 8 | 4.7 | 452 | 310 | 378 | 195/45R15 195/50R16 | |

B185R15-1 | 277 | 23 | 13 | 7 | 5 | 490 | 306 | 380 | ||

RB15-2 | 285 | 21.5 | 12 | 8 | 5 | 500 | 305 | 384 | ||

RB1503 | 285 | 21.5 | 12 | 7.5 | 4.5 | 498 | 310 | 386 | RTB15-386 | |

P408 | 286 | 21.4 | 11.6 | 9.5 | 6.35 | 495 | 316 | 394 | ||

B195R15-2 | 277 | 21 | 13 | 7 | 5 | 490 | 345 | 415 | ||

B205R16-2 | 285.7 | 21.4 | 11.66 | 9.6 | 4.06 | 508 | 322 | 416 | 195/65R15 205/55R16 | |

B205R16-2(2) | 285.7 | 21.4 | 11.66 | 9.6 | 4.06 | 508 | 322 | 416 | 195/65R15 205/55R16 | |

B205R16-2(3) | 285.7 | 21.4 | 11.66 | 9.6 | 6.3 | 508 | 322 | 416 | 195/65R15 205/55R16 | |

B205R16-3 | 285.7 | 21.4 | 11.66 | 9.6 | 4.06 | 508 | 322 | 416 | 195/65R15 205/55R16 | |

B368D | 276 | 20.5 | 14.2 | 10 | 5.2 | 448.6 | 363.6 | 420 | ||

B368D | 276 | 20.5 | 14.2 | 10 | 5.2 | 448.6 | 363.6 | 420 | ||

RTB15-415 | 277 | 22 | 12 | 7 | 4.5 | 530 | 320 | 420 | 205/60R15 | |

B205R15-1 | 277 | 22 | 13 | 8 | 4.7 | 546 | 305 | 420 | 195/65R15 205/60(70/75)R15 | |

B205R15-1(2) | 277 | 21 | 13 | 9 | 6 | 546 | 305 | 420 | 195/65R15 205/60(70/75)R15 | |

RB1504 | 285 | 22 | 12 | 8 | 5.3 | 522 | 340 | 424 | ||

JS0750 | 276 | 23 | 12.5 | 8 | 5 | 510 | 325 | 430 | 205/75R15/16 225/60R15/16 | |

B185R16-1 | 277 | 21 | 13 | 7 | 5 | 550 | 325 | 435 | 185/215R15/16 | |

B185R16-2 | 277 | 21 | 13 | 7 | 5 | 550 | 325 | 435 | 185/215R15/16 | |

B185R16-3 | 277 | 21 | 13 | 7 | 4.8 | 550 | 325 | 435 | 185/215R15/16 | |

RTB15-456 | 277 | 23.5 | 12.5 | 7.5 | 5 | 566 | 330 | 456 | ||

B225R16-2 | 272 | 22 | 12.7 | 8.5 | 4 | 540 | 360 | 464 | ||

B225R16-2(2) | 272 | 22 | 12.7 | 8.5 | 5 | 540 | 360 | 464 | ||

JS0850 | 276 | 23 | 12.5 | 8 | 5 | 510 | 380 | 470 | 215/75R16 235/70R16 | |

RB15-1 | 280 | 22 | 12 | 8 | 5 | 580 | 376 | 495 | ||

B225R15-1 | 277 | 21 | 13 | 7 | 5 | 576 | 367 | 508 | 235/75R15 225/75R16 | |

B225R15-2 | 277 | 22 | 13 | 7 | 4.7 | 576 | 368 | 508 | 235/75R15 | |

B235R16-1 | 277 | 23 | 13 | 7 | 5 | 590 | 404 | 552 | 215/85R16 235/60R16 | |

B235R16-3 | 277 | 21 | 13 | 7 | 5 | 590 | 404 | 552 | ||

JYBD0250 | 276 | 23.5 | 12.5 | 8 | 5 | 540 | 422 | 570 | 245/65R16 285/75R16 | |

B265R16-1 | 277 | 21 | 13 | 7 | 5 | 620 | 389 | 570 | LT245R17 LT265/75R16 | |

RTB15-570 | 277 | 24 | 13 | 8.5 | 5.2 | 645 | 380.5 | 570 | 235/80R16 265/75R16 | |

RTB15-614 | 276 | 23.5 | 13 | 8 | 5 | 660 | 415 | 614 | ||

RB16-10 | 310 | 21 | 12 | 8 | 5.5 | 460 | 296 | 346 | ||

JY0145 | 300 | 25 | 14.2 | 8 | 4.5 | 476 | 298 | 370 | 205/40R17 | |

RB16-3 | 310 | 21 | 12 | 8 | 5.5 | 480 | 308 | 370 | ||

RBSC1604 | 310 | 21 | 12 | 8 | 4.5 | 498 | 326 | 394 | ||

JTB305R400 | 305 | 21.5 | 12 | 8.2 | 5.2 | 500 | 325 | 400 | ||

P420 | 311 | 21.4 | 11.6 | 9.5 | 6.35 | 508 | 342 | 400 | ||

JY1145 | 300 | 22 | 14.2 | 10 | 4.5 | 525 | 270 | 406 | 205/50/55R17 235/40R18 | |

RTB16-408 | 310 | 23 | 12 | 7.5 | 4.5 | 515 | 325 | 408 | 225/55R16 | |

RTB16-413 | 304 | 23 | 12 | 7.5 | 4.5 | 520 | 340 | 413 | 225/55R16 | |

B215R16-1 | 300 | 22 | 12 | 7 | 5 | 500 | 356 | 426 | ||

B205R16-1 | 304 | 23.3 | 12.8 | 7 | 4.5 | 438 | 394 | 426 | 205/215R16/17/18 | |

RBSC1605 | 310 | 21 | 12 | 8 | 4.5 | 536 | 370 | 440 | ||

JS1045 | 300 | 25 | 14.2 | 10 | 4.5 | 560 | 294 | 448 | ||

RB1601 | 310 | 24 | 12 | 8 | 6 | 590 | 346 | 460 | ||

B12.5X385X562 | 299 | 22 | 12 | 8 | 4.5 | 562 | 385 | 476 | ||

B225R16-1 | 299 | 22 | 13 | 7 | 5 | 588 | 360 | 480 | 225R16 | |

B225R16-1(3) | 299 | 22 | 13 | 7 | 6 | 588 | 360 | 480 | 225R16 | |

B225R16-1(2) | 299 | 22 | 13 | 7 | 5 | 588 | 360 | 481 | 225R16 | |

B225R16-1(4) | 299 | 23 | 13 | 7 | 5.8 | 588 | 361 | 481 | 225R16 | |

JY1545 | 300 | 25 | 14.2 | 8 | 4.5 | 580 | 370 | 484 | ||

JY1545-2 | 300 | 25 | 14.2 | 8 | 4.5 | 580 | 408 | 514 | ||

B235R16-2 | 299 | 22 | 13.7 | 10 | 4.5 | 588 | 408 | 518 | ||

B235R16-2(2) | 299 | 22 | 13.7 | 10 | 5 | 588 | 408 | 518 | ||

B12.5X445X562 | 299 | 22 | 12 | 8 | 4.5 | 562 | 445 | 536 | ||

JS1445 | 300 | 24 | 14 | 8 | 5 | 640 | 400 | 573 | 265/60R18 285/70R18 | |

RTB16-606 | 300 | 24 | 13 | 8 | 5 | 680 | 390 | 606 | ||

B345R16-1 | 300 | 24 | 12 | 10 | 6 | 790 | 500 | 760 | ||

RTB17-283 | 336 | 22 | 12 | 8 | 5 | 495 | 225 | 283 | 185/35R17 165/40R17 | |

B205R17-3 | 336.5 | 24 | 12 | 8 | 5 | 470 | 288 | 326 | ||

B205R17-2 | 336.5 | 24 | 12 | 8 | 4.5 | 470 | 300 | 338 | 205/40R17 | |

B205R17-2(2) | 336.5 | 24 | 12 | 8 | 4.5 | 470 | 300 | 338 | 205/40R17 | |

JTB1703 | 336 | 24 | 12 | 7.5 | 5 | 476 | 311 | 350.5 | ||

B205R17-1 | 336.5 | 22 | 11.8 | 7.5 | 4.5 | 500 | 320 | 372 | 205/45(50)R17 225/45R17 | |

B205R17-1(2) | 336.5 | 21.4 | 11.66 | 9.55 | 6.3 | 500 | 320 | 372 | 205/45(50)R17 225/45R17 | |

B205R17-1(3) | 336.5 | 21.4 | 11.66 | 9.55 | 6.3 | 500 | 320 | 372 | 205/45(50)R17 225/45R17 | |

B215R17-1 | 336.5 | 21.4 | 11.7 | 9.6 | 4.5 | 500 | 330 | 382 | ||

B235R18-1 | 336.55 | 21.88 | 11.66 | 9.551 | 4.5 | 490 | 338 | 390 | 225/40R18 | |

JTB335R391 | 335 | 23.5 | 12 | 8.2 | 5.2 | 498 | 300 | 391 | ||

B235R17-1 | 336.5 | 21.88 | 11.66 | 9.6 | 4.5 | 516 | 330 | 392 | ||

17-J-380 | 334 | 24.8 | 13.4/11.9 | 11 | 4.5 | 520 | 338 | 398 | ||

17-J-380-1 | 334 | 22.5 | 13 | 7.5 | 4.5 | 530 | 325 | 400 | ||

RB1710 | 336 | 24 | 12 | 7.5 | 4.5 | 525 | 338 | 405 | 235/50R17 | |

B225R17-1 | 336.55 | 21.88 | 11.66 | 9.551 | 4.5 | 520.7 | 368 | 424 | 225/50R17 | |

17-J-425B | 334 | 24 | 12.5 | 8.7 | 4.5 | 560 | 335 | 425 | 215/60R17 235/65R17 | |

DP396 | 336 | 21.88 | 11.66 | 9.5 | 4.06 | 590 | 315 | 425 | ||

B225R17-1(2) | 336.55 | 22.5 | 11.7 | 7.5 | 4.5 | 520.7 | 366 | 427 | 225/55R17 | |

B225R17-2 | 336 | 22.5 | 12.5 | 8 | 5 | 560 | 346 | 433 | 225/60R17 | |

B443D | 334 | 20.5 | 14.7 | 9 | 5.3 | 440 | 418 | 450 | ||

17-J-450B | 334 | 24 | 12.5 | 8.7 | 4.5 | 595 | 335 | 450 | 225/65R17 235/65R17 | |

B255R17-1 | 336.5 | 21.4 | 11.66 | 9.55 | 4.5 | 540.7 | 398 | 460 | ||

B255R17-1(2) | 336.5 | 21.4 | 11.66 | 9.55 | 5.5 | 540.7 | 398 | 460 | ||

RTB17-480 | 336 | 23 | 12 | 8 | 5.2 | 590 | 370 | 480 | 245/70R17 | |

B235R17-2 | 336.5 | 21.88 | 11.66 | 9.6 | 4.5 | 610 | 398 | 500 | ||

B265R17-1 | 336 | 21 | 12 | 9.5 | 4.5 | 620 | 412 | 520 | ||

B265R17-2 | 336 | 21 | 12 | 9.5 | 4.5 | 620 | 462 | 570 | ||

RTB17-610 | 336 | 24 | 12 | 8 | 5.5 | 710 | 412 | 610 | 35×12.5R17 315/70R17 | |

18B | 356 | 23 | 12 | 8 | 6 | 480 | 296 | 337 | ||

18A | 356 | 23 | 12 | 8 | 6 | 496 | 326 | 372 | 245/35R18 | |

18A-1 | 356 | 23 | 12 | 8 | 5 | 496 | 326 | 375 | ||

B14X310X560 | 350 | 22 | 14 | 9 | 5 | 560 | 310 | 390 | ||

18-J-378 | 360 | 24.8 | 13.2 | 11 | 4 | 530 | 340 | 393 | ||

JS2045 | 350 | 25 | 14.2 | 8 | 4.7 | 550 | 320 | 408 | ||

18-J-410B | 360 | 24 | 12.5 | 8.7 | 4.5 | 565 | 330 | 410 | 215/55R18 | |

B255R18-1 | 353 | 24 | 12.9 | 8 | 6 | 500 | 368 | 414 | 255/265/35R18 235/245/35R19 | |

JS2345 | 350 | 25 | 14.2 | 8 | 4.7 | 555 | 340 | 428 | 225/40R19 245/40R19 | |

B14X350X560 | 350 | 22 | 14 | 9 | 5.3 | 560 | 350 | 430 | ||

B14X350X560-2 | 350 | 22 | 14 | 9 | 5.3 | 560 | 350 | 430 | ||

B235R18-2 | 360 | 21.88 | 11.66 | 9.55 | 4.5 | 572 | 356 | 432 | 235/50(55)R18 235/60R18 | |

B235R18-2(3) | 360 | 21.88 | 11.66 | 9.55 | 5.5 | 572 | 356 | 432 | 235/50(55)R18 235/60R18 | |

B235R18-2(4) | 360 | 21.88 | 11.66 | 9.55 | 4.5 | 572 | 356 | 432 | 235/50(55)R18 235/60R18 | |

RTB18-442 | 356 | 23 | 13 | 7.5 | 4.5 | 580 | 345 | 442 | 225/55R18 235/50R18 | |

B14X340X610 | 350 | 22 | 14 | 9 | 5 | 610 | 340 | 443 | ||

B14X340X610-2 | 350 | 22 | 14 | 9 | 5 | 610 | 340 | 443 | ||

JS2245 | 350 | 24 | 13 | 8 | 4.7 | 564 | 360 | 453 | 235/35R19 275/30R20 | |

B255R18-2 | 353 | 24 | 12.9 | 8 | 6 | 544 | 390 | 454 | 255/45R18 235/50R18 | |

18-J-460B | 360 | 24 | 12.5 | 8.7 | 4.5 | 605 | 360 | 460 | 235/60R18 255/55R18 | |

B235R18-2(2) | 360 | 21.88 | 11.66 | 9.55 | 4.5 | 572 | 386 | 462 | 235/50(55)R18 235/60R18 | |

B14X370X610 | 350 | 22 | 14 | 9 | 5 | 610 | 370 | 473 | ||

B14X370X610-2 | 350 | 22 | 14 | 9 | 5 | 610 | 370 | 473 | ||

B14X385X610 | 350 | 22 | 14 | 9 | 5 | 610 | 370 | 488 | ||

NCY B14X385X610 | 350 | 22 | 14 | 9 | 5 | 610 | 385 | 488 | ||

B14X400X610 | 350 | 22 | 14 | 9 | 5 | 610 | 400 | 503 | ||

B14X400X610-2 | 350 | 22 | 14 | 9 | 5 | 610 | 430 | 503 | ||

NCY B14X400X610 | 350 | 22 | 14 | 9 | 5 | 610 | 400 | 503 | ||

B14X420X610-1 | 350 | 22 | 14 | 9 | 5 | 610 | 400 | 523 | ||

NCY B14X420X610 | 350 | 22 | 14 | 9 | 5 | 610 | 420 | 523 | ||

NCY B14X430X610 | 350 | 22 | 14 | 9 | 4.5 | 610 | 430 | 536 | ||

B14X460X570(PNCS) | 350 | 22 | 14 | 9 | 4.5 | 570 | 460 | 539 | ||

18H | 356 | 23 | 12 | 8 | 5 | 640 | 441 | 550 | ||

B14X480X570(PNCS) | 350 | 22 | 14 | 9 | 4.5 | 570 | 480 | 559 | ||

B275R18-1 | 353 | 23.5 | 13 | 8 | 5 | 680 | 375 | 560 | 275/70R18 | |

NCY B14X460X610 | 350 | 22 | 14 | 9 | 5 | 610 | 460 | 563 | ||

NCY B14X480X610 | 350 | 22 | 14 | 9 | 5 | 610 | 480 | 583 | ||

RTB18-596 | 356 | 23.5 | 12 | 8 | 5 | 680 | 446 | 596 | 35*12.5R18LT | |

B215R19-2 | 380 | 24 | 12.7 | 7 | 5 | 500 | 288 | 334 | ||

B235R19-1 | 380 | 24 | 12.7 | 7 | 5 | 500 | 314 | 360 | ||

RTB19-378 | 380 | 23 | 13 | 7.5 | 4.5 | 555 | 310 | 378 | 245/35R19 | |

B245R19-2 | 380 | 24 | 12.7 | 7 | 4.2 | 520 | 334 | 380 | 245/35R19 | |

B215R19-1 | 378 | 24 | 12.7 | 8 | 6 | 500 | 350 | 385 | 215/225/35R19 | |

B15X300X600 | 375 | 22 | 14 | 9 | 5 | 600 | 300 | 402 | ||

B275R19-1 | 380 | 24 | 13 | 7 | 4.5 | 535 | 355 | 415 | 265/35R19 275/30R19 295/30R19 | |

19-J-435 | 380 | 23.5 | 11.8 | 11 | 4.5 | 580 | 356 | 435 | ||

B15X350X600 | 375 | 22 | 14 | 9 | 4.5 | 600 | 350 | 452 | ||

B245R19-1 | 387 | 21.88 | 11.66 | 9.55 | 4.5 | 562 | 400 | 458 | 235/55R19 245/45(55)R19 | |

B15X350X620 | 375 | 22 | 14 | 9 | 4.5 | 620 | 350 | 463 | ||

19-J-465B | 387 | 24 | 12.5 | 8.7 | 4.5 | 605 | 376 | 465 | 245/55R19 255/50R19 | |

B265R19-1 | 387 | 21.88 | 11.66 | 9.55 | 4.5 | 584 | 402 | 473 | ||

B15X370X620 | 375 | 22 | 14 | 9 | 4.8 | 620 | 375 | 483 | ||

RTB19-506 | 380 | 23.5 | 12.5 | 8.5 | 5 | 630 | 390 | 506 | 255/55R19 275/55R19 | |

B225R20-2 | 403 | 24 | 13 | 7 | 4.5 | 530 | 320 | 360 | 225/35R20 | |

B225R20-1 | 403 | 24 | 12.7 | 8 | 6 | 528 | 338 | 378 | 225/35R20 | |

B245R20-1 | 396 | 24 | 12.5 | 8 | 4.5 | 570 | 346 | 404 | 245/45R20 | |

B245R20-1(2) | 396 | 24 | 12.5 | 8 | 6 | 570 | 346 | 404 | 245/45R20 | |

B245R20-1(3) | 396 | 24 | 12.5 | 7 | 3.8 | 570 | 346 | 404 | 245/45R20 | |

RTB22-422 | 410 | 25 | 14 | 7 | 4.5 | 590 | 340 | 422 | 235/30R22 255/30R22 | |

B265R20-1 | 403 | 24 | 13 | 7.5 | 4.5 | 590 | 375 | 440 | 265/40R20 | |

B285R20-1 | 403 | 24 | 12.7 | 8 | 5.5 | 540 | 402 | 444 | ||

B275R20-1 | 403 | 24 | 12.7 | 8 | 4.5 | 600 | 402 | 460 | ||

B255R20-1 | 396 | 24 | 12.5 | 8 | 4..5 | 600 | 426 | 490 | ||

B255R20-1(2) | 396 | 24 | 12.5 | 8 | 6 | 600 | 426 | 490 | ||

B285R20-2 | 403 | 24 | 12.7 | 8 | 5.5 | 634 | 440 | 510 | ||

RTB20-558 | 400 | 24 | 12 | 8 | 5 | 690 | 420 | 558 | ||

RTB20-606 | 396 | 24 | 13 | 8 | 5.5 | 740 | 430 | 606 | 37*13.5R20LT 36*13.50R20LT | |

B295R22-1 | 419 | 21.4 | 11.7 | 9.5 | 6.2 | 627 | 278 | 525 | 295/45R22 | |

RTB21-370 | 428 | 25 | 14.2 | 8 | 4.3 | 580 | 320 | 370 | 245/35R21 | |

RTB21-400 | 428 | 25 | 14.2 | 8 | 4.3 | 580 | 350 | 400 | 275/30R21 | |

RTB21-430 | 428 | 25 | 14.2 | 8 | 4.3 | 610 | 365 | 430 | 245/45R21 315/35R21 | |

RTB21-460 | 428 | 25 | 14.2 | 8 | 4.3 | 610 | 395 | 460 | 275/45R21 325/30R21 | |

RTB22-383 | 454 | 24 | 12.7 | 7.5 | 4.2 | 580 | 345 | 383 | 245/30R22 255/30R22 | |

B255R24-1 | 454 | 24 | 12.7 | 8 | 5 | 600 | 384 | 426 | ||

RTB22-463 | 454 | 24 | 12.7 | 8 | 5 | 650 | 385 | 463 | 285/40R22 295/40R22 33*12.5R22LT 305/40R22 31*13.50R22LT | |

B305R22-1 | 454 | 24 | 12.7 | 8 | 4.5 | 656 | 440 | 500 | ||

B305R22-1(2) | 454 | 24 | 12.7 | 8 | 6 | 656 | 440 | 500 | ||

B305R24-1 | 454 | 24 | 12.7 | 8 | 5.5 | 660 | 470 | 526 | ||

RTB22-570 | 454 | 24 | 12.7 | 8 | 5 | 700 | 460 | 570 | 35*13.50R22LT 33*14.50R22LT 35*15.50R22LT 37*13.5R22LT | |

RTB24-482 | 470 | 24 | 14 | 8 | 5.5 | 690 | 390 | 482 | 285/40R24 275/30R26 | |

RTB24-512 | 470 | 24 | 14 | 8 | 5.5 | 690 | 420 | 512 | 295/30R26 305/30R26 | |

RTB24-552 | 470 | 24 | 14 | 8 | 5.5 | 690 | 460 | 552 | 315/35R26 | |

RTB24-593 | 470 | 24 | 14 | 8 | 5.5 | 700 | 495 | 593 | 35*15.50R24LT 36*14.50R24LT | |

B305R26-1 | 555 | 24 | 14 | 7 | 5 | 670 | 400 | 440 | ||

RTB28-480 | 555 | 24 | 12 | 8 | 5 | 710 | 420 | 480 | 35*13.50R26LT 37*13.50R26LT 36*14.50R26LT | |

JTBR28-1 | 555 | 24 | 13 | 8 | 5 | 750 | 502 | 560 |

Recommendations for achieving best Bladder Performance:

FENGFU Bladders are manufactured using a well proven long-lasting heat conductive butyl rubber compound.

The high degree of elasticity of the bladder guarantees trouble-free molding and stripping.

The following points should be considered under all circumstances:

10. We suggest that you store the curing bladder at least 90 days from the date of production before use.

11. Please resume the curing bladder to its original shape 24 hours prior to use.

12. Before mounting curing bladders, please check whether the curing bladder size match as the tyre size. We suggest you choosing the proper clamping size as per curing bladder clamping parameters.

13. Before mounting bladders into curing press we recommend to pre-treat the bladders with a bladder coating material to optimize your curing bladder performance and extend the curing bladder life time.

14. Spraying of isolation agent inside the green tyre is necessary in order to avoid sticking, trapped air or stripping problems

15. We suggest you do not use any lubricants during clamping the curing bladders, please pay attention not to use any diluted water-solubility silicon latex and not to drop it on the tyre mould surface.

16. When you test the curing bladder air tightness, the elongation of curing bladders should be proper in order to avoid destroying the curing bladder or causing other problems.

17. The strict deoxidization of overheated water and nitrogen vulcanization can evidently extend the curing bladder service life.

18. Before tire curing starts, the bladder should be fully warmed up. For this, the machine should be operated according to the press manual.

19. In case of pre-inflating during the warm up, the bladder outside diameter must not exceed the tire sidewall plate outside diameter of the tire mold, in order to avoid non-symmetric deformation.

20. If the bladder has cooled down after an interruption in the curing process, it is imperative to warm it up again.

21. Please fill in the Curing Bladder Performance Record Form seriously, in order to get better service when curing bladders quality problem come out .

To optimize your bladder performance furthermore we recommend the application of a permanent bladder coating material .

We can offer you various coating material applied on our bladders.

For our customers,we offer one-stop service to optimize bladder application and performance.

In case of any questions , please contact us freely.

B TYPE SEMI-STEEL RADIAL TYRE CURING BLADDER FOR PCR & LTR

C TYPE SEMI-STEEL RADIAL TYRE CURING BLADDER FOR PCR & LTR

B TYPE ALL STEEL RADIAL TYRE CURING BLADDER FOR TBR

A TYPE RADIAL TYRE CURING BLADDER FOR PCR & LTR

AB TYPE RADIAL TYRE CURING BLADDER FOR PCR & LTR

B TYPE CURING BLADDER FOR BIAS TRUCK & BUS (TBB) TIRE

B TYPE CURING BLADDER FOR BIAS INDUSTRIAL & OTR TIRE

B TYPE CURING BLADDER FOR RADIAL INDUSTRIAL & OTR TIRE

B TYPE CURING BLADDER FOR BIAS AGRICULTURAL (AG) TIRE

B TYPE CURING BLADDER FOR MERIDIAN AGRICULTURAL (MG) TIRE

B TYPE CURING BLADDER FOR MOTORCYCLE TIRE

- Name

- Mobile Phone

- *Title

- *Content

- What is tire building bladder ?Mar 20,2025

- TYRE CURING BLADDER STORAGE CONDITIONMar 18,2025